Description

In recent years, inks have also been used to make the transparent conductive layer used in solar cells. Inks based on silver and graphene nanowires are the most important types of these inks.

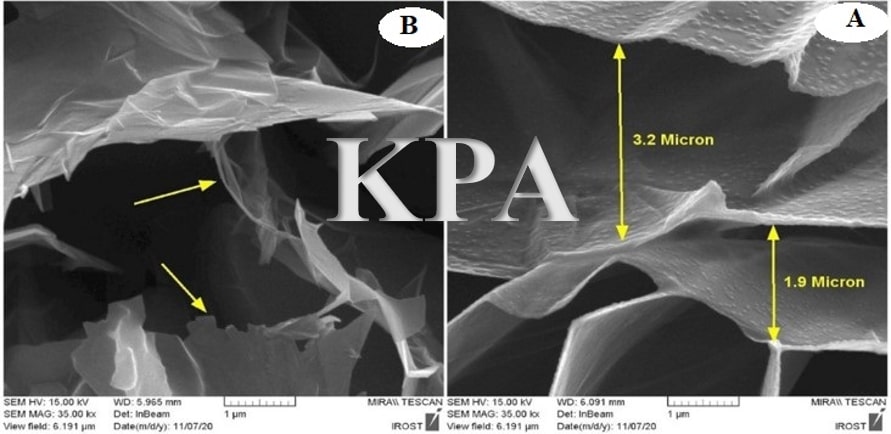

Graphene has become a unique material due to its extraordinary properties in electrical conductivity and thermal conductivity, high density and mobility of charge carriers, optical properties and mechanical properties.

Due to these extraordinary properties, the new allotrope of carbon is considered a very suitable candidate for replacing silicon in the next generation of photonic and electronic components, and thus it has attracted unprecedented attention in fundamental and applied research. This material with high electrical conductivity, flexibility and mechanical and thermal stability is considered as a new electrode, especially in organic electronic devices.

A typical printer ink consists of filler, binder, additive and solvent. The selection of these components ultimately depends on the type of printing method to be considered. Fillers are the active component of the ink that provides the properties required for specific applications. Depending on the application, fillers can be metallic, ceramic, organic, or a combination of them.

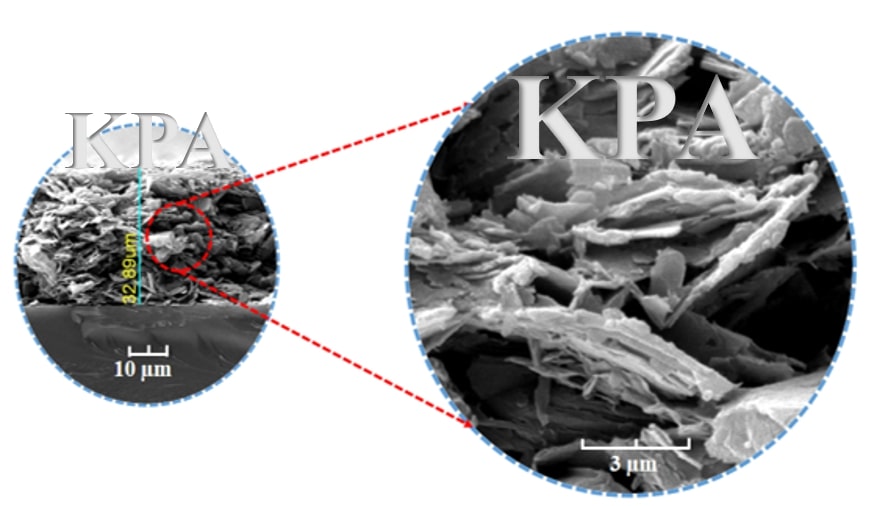

With rapid advances in nanotechnology, researchers have been able to create conductive inks using conductive nanomaterials such as nanosheets, nanowires, nanoparticles, or their conductive composites. The combination of nanoscience features with printing technology has led to new fields of low-cost electronics. Another important component of the ink is the binder, which is a polymeric substance that helps disperse the fillers homogeneously in the ink. After printing, binders hold the ink components together, and also help bond the print to the substrate after evaporation.

The newest inks are graphene-based inks. Graphene is much more conductive than carbon and is the thinnest material available. Graphene ink as carbon-based inks is a suitable alternative to metal nanoparticle-based inks, which had manufacturing cost limitations and resistance limitations. Unstable electrons in the graphene structure cause current transfer. Graphene also shows significant solubility and dispersion in a number of solvents. Graphene-based inks have very high conductivity and are used in a wide range of substrates, including paper and plastic. They are extremely flexible. These inks have better surface stability than conductive composites and carbon-based inks and are cheaper than metal inks. Graphene ink is made of graphene and various polymers, surfactants and techniques for producing functional groups that reduce the accumulation and help in the dispersion of carbon/graphene nanomaterial inks.

One of the applications of conductive inks is in the printing of electrical circuits, the production of sensors and biosensors. Also, due to the polymer compounds used in the ink formulation, there is the ability to print elastic, flexible and self-healing devices.

Download – Graphene Ink TDS and MSDS

KPA company operates in the field of production of conductive graphene ink product with the best quality and price.

To place an order and if you need advice as well as to inquire about the price of conductive graphene ink, you can enter the page (contact us) and contact our experts.

https://graphenika.com/contact/

Also, see the following pages for more information on the application of conductive graphene ink.

https://graphenika.com/en/contact/

https://graphenika.com/en/portfolio/printed-electronics/

https://graphenika.com/en/gas-sensors/

Thanks to dear Naghma Gholam Alizadeh for this article:

Stencil Printing of Highly Conductive Graphene Ink Towards Flexible Electrochemical Biosensors for Glucose Monitoring

Reviews

There are no reviews yet.